Posted on

25 juin 2019

in

Mixed waste sorting installation – video

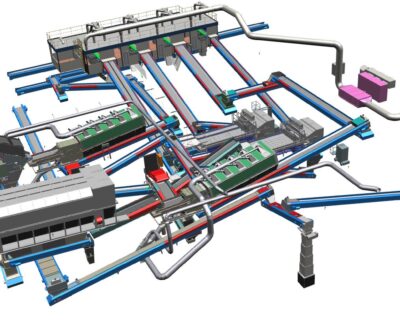

One of our most recent projects has been a turn-key delivery of a mixed waste sorting installation for Suez in Belgium, where the line processes 23 Tons/hour of unshredded material.

This installation uses 2 screens to sort the waste into 3 sizes. Depending on their fraction size, they are either cleaned up by an magnetic overband system, separated in heavies and lights by a wind shifter, or directly fed into to the sorting cabin ready for hand picking. This customer based methodology ensures them with a maximum purity on the various outfeed fractions, while enabling a high throughput.

Related posts

6 juillet 2018

Drum screen on the way to project site

On the move to France! This trommel screen machine is part of a turnkey process installation we [...]

Read more12 juillet 2019

Video from our recycling installation in Germany available

Watch our latest video from our recent project. A waste sorting plant for commercial waste with [...]

Read more

Anglais

Anglais Allemand

Allemand Russe

Russe